In April 2023, the Group established the Sustainability Committee to promote its sustainability initiatives and expressed its support for the TCFD (Task Force on Climate-related Financial Disclosure) recommendations. Taking this opportunity, we will further strengthen our analysis and response to the risks and opportunities posed by climate change to our business, expand the disclosure of related information, and contribute to the realization of a decarbonized society by 2050.

The Sustainability Committee is chaired by the President and consists of the director in charge of management, the head of the Group's administrative division, and members appointed from each Group company. The committee regularly submits proposals and reports to the Board of Directors, and the Board of Directors supervises the progress of the committee's activities.

To identify risks and opportunities from climate change, we analyzed the impacts of our business operations in 2030 and 2050 under the 1.5°C scenario and the 4°C scenario, based on information published by the Intergovernment Panel on Climate Change (IPCC) and the International Energy Agency (IEA). and 4°C scenarios for the Group's operations, and analyzed the impacts in 2030 and 2050.

|

Classification |

Risk item |

Degree of in-fluence |

Impact on business |

Countermeasure |

|

|

Transition risk |

Policy and Regulatory Risk |

Increase in GHG emission prices |

Small |

Due to the introduction of the carbon tax, energy costs such as electricity and gas costs are passed on to prices, resulting in an increase in manufacturing costs. |

Further implementation of energy conservation. Promote the selection of facilities that enable energy-efficient production when introducing or updating new facilities. Establish efficient production and logistics systems at each production site. |

|

Market risk |

Increased cost of raw materials |

Medium |

Due to the introduction of the carbon tax, raw materials (chocolate, cream and cheese made from dairy products, etc.) and packaging materials received a price pass-through, increasing production costs. |

Strive to reduce production loss by increasing the percentage of good products. Curb procurement cost increases by strengthening cooperation with raw material suppliers. |

|

|

Changes in Customer Behavior |

Small |

Increased interest in environmentally friendly packaging materials as consumers become more environmentally conscious. Manufacturing costs increase due to the shift to environmentally friendly packaging materials to meet consumer needs. |

Promote the use of environmentally friendly packaging materials (FSC certified paper, biomass plastic, etc.). Promote recycling of food scraps into compost, fertilizer, etc. |

||

|

Physical risk |

Acute risk |

Increased severity and frequency of extreme weather events such as cyclones and floods |

Medium |

When transportation infrastructure is affected by torrential rains, typhoons, floods, etc., demand for souvenirs for travel is reduced. |

Strengthen development and sales of home-demand products. Establish diverse sales channels with brands for each region in Japan; strengthen sales of gift products through e-commerce. |

|

Chronic risk |

Increase in average and maximum temperatures |

Medium |

Rising average temperatures lead to a decrease in the harvest and production of the main raw material.

Decrease in production volume, which may lead to lower earnings and impact on the purchase price of raw materials. |

Procure raw materials from multiple raw material suppliers. For raw mate-rials that are expected to be in short supply, we will procure them from different production areas and pro-mote the development of product manufacturing using alternative raw materials. |

|

|

Opportunity |

(the) market (as a concept) |

Increase in average and maximum temperatures |

Small |

Demand for frozen gifts (ice cream, ice cream, frozen cakes, etc.) is expected to increase due to higher average and maximum temperatures. |

Develop products that are compatible with frozen gifts. Study the introduction of packaging materials that can be carried for long periods of time. |

* Minor impact (less than 1 billion yen) Medium impact (1 billion yen to less than 5 billion yen) Major impact (5 billion yen or more)

The Group Business Management Division, which oversees business-related risks, identifies company-wide risks and determines the policies for dealing with them, and promotes appropriate management and response to risks. Climate change-related risks are discussed by the Sustainability Committee, to which the Group Corporate Administration Division belongs, to enable integration with company-wide risk management. The Sustainability Committee also deliberates on the materiality assessment of risks related to climate change using scenario analysis in line with TCFD recommendations, and reports the results to the Board of Directors, which oversees them.

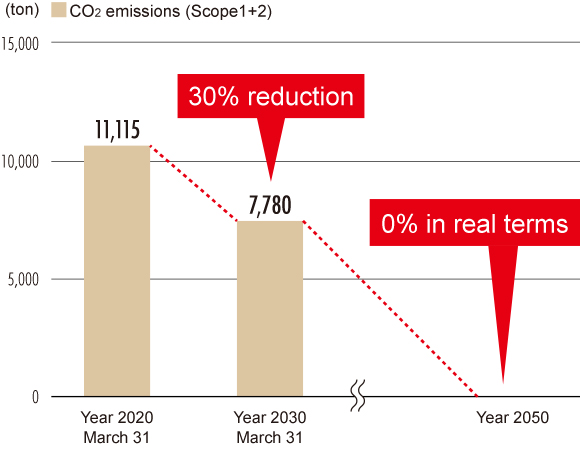

To mitigate climate change, the Minebea Group aims to reduce CO2 emissions (Scope 1 + 2) at Group manufacturing sites in Japan by 30% by 2030 compared to the fiscal year ended March 31, 2020 (11,115 tons) and to achieve virtually zero emissions of CO2 and other greenhouse gases by 2050.

Greenhouse Gas Emissions Targets

The Group is promoting the replacement of fluorescent and mercury lamps in factories, warehouses, and offices with LED lighting, which reduces electricity consumption while maintaining illumination levels that take occupational safety into consideration.

In addition, we are working to save energy and reduce CO2 emissions by adopting electric forklifts for moving cargo in warehouses and other locations and promoting the use of hybrid cars and other eco-friendly vehicles in our sales fleet.

Kotobuki Seika has installed a charging station in the parking lot of its Kotobuki Castle of Confectionery, a direct sales store and factory, to promote the use of electric vehicles that do not emit carbon dioxide when running, which is expected to help combat global warming. K.C.I.S.I. has successfully reduced electricity consumption by approximately 5% per year by introducing a system to operate refrigerators at reduced intervals.

Shkreli generates renewable energy by generating biogas from food waste through the action of microorganisms (methane fermentation).

In addition, the Kujuukushima Group supplies food waste to incineration facilities that practice thermal recycling*, thereby reducing CO2 emissions compared to conventional incineration.

*Recycling method that recovers and utilizes "heat energy" generated from waste incineration process.

In order to make effective use of limited resources and realize a low-impact society, the Group is promoting the use of recycled paper for product packaging. In addition to using FSC- and PEFG-certified copy paper at our business sites, we are also reviewing our business systems, such as approval and settlement flows, to promote paperless operations and DX throughout the supply chain.

- 拡大

- Boxes made of recycled paper

Kotobuki Seika collects confectionery scraps and other food residues discharged from its factories through a licensed collection and transportation company. The food residues are then crushed and mixed by a recycling company registered under Article 11 of the Food Recycling Law, and after fermentation in a completely enclosed fermentation tank, they are recycled as compost. This compost is supplied to local farms and farmers, contributing to the cultivation of superior vegetables and creating a recycling cycle that uses food residues as a resource. Similarly, Keishii recycles the compost into feed for pigs.

Food Resource Recycling Cycle